The Impact of Trump's Proposed Tariffs on Automakers and the Challenges Ahead

- Get link

- X

- Other Apps

The recent announcement of a 25% tariff on vehicles imported from Mexico and Canada by former President Trump has sent ripples through the automotive industry. While the immediate focus is on complete vehicles, the ripple effects of this policy could disrupt the entire supply chain. This blog explores how these tariffs could impact costs, production strategies, and supply chain dynamics, offering actionable insights for procurement and supply chain professionals.

1. Tariff-Driven Cost Increases: A Double-Edged Sword

Current Scope: Complete Vehicles Only

As of now, the proposed tariffs target only finished vehicles imported from Mexico and Canada, sparing parts suppliers. However, the downstream effects could significantly disrupt the supply chain. Automakers facing reduced price competitiveness may demand cost reductions from their suppliers, forcing Tier 1 and Tier 2 suppliers to absorb financial pressures or renegotiate contracts.

Key Implications:

- Pressure on Supplier Margins: Automakers may compel suppliers to lower prices to offset the tariff impact, especially for components integrated into affected vehicle lines.

- Increased Cost of Doing Business: A cascading effect could arise where upstream suppliers face production slowdowns, negatively impacting both local and global operations.

- Competitive Erosion: Automakers importing vehicles could lose ground to domestic manufacturers who aren’t subject to the same costs, disrupting long-standing business relationships.

Example:

An automaker importing a $30,000 vehicle could face $7,500 in tariff-related costs, translating into retail price hikes or deeper negotiations with suppliers to share the burden.

2. The Ripple Effect on U.S. Automotive Production Capacity

Despite the proposed tariffs' goal of increasing domestic production, current U.S. factory utilization rates indicate underperformance. Many plants are operating below their maximum output, leaving room for increased production without significant new investments.

Questions to Address:

Can U.S. Factories Fill the Gap?

- Review current production capacity in key facilities like GM's Arlington or Ford's Dearborn plant.

- Estimate how much of the imported vehicle volume could realistically be absorbed domestically.

Challenges in Scaling Up Production:

- Labor shortages and increased costs for additional shifts or facility upgrades.

- The timeline required to ramp up production capacity versus the immediate impact of tariffs.

Example:

If a U.S. automaker imports 300,000 units annually from Mexico, but domestic plants operate at 85% capacity, increasing production to meet demand would require overcoming significant logistical hurdles.

3. Automaker-Specific Case Studies: A Strategic Outlook

Tesla

Tesla’s plans for a $10 billion gigafactory in Monterrey, Mexico, face uncertainty. Tariffs could delay or alter its strategy to localize manufacturing in Mexico, a key part of its global EV expansion.

Ford and GM

Both companies rely heavily on Mexican facilities for trucks and SUVs. These vehicles are high-margin products, and tariffs could erode profitability or compel shifts in production back to U.S. plants, though this transition could take years.

Opportunities for Rivals

- Japanese automakers like Toyota and Honda could capitalize on their U.S.-based manufacturing plants, avoiding tariffs and undercutting competitors.

- German manufacturers like BMW and Mercedes-Benz might further expand their existing Southern U.S. plants.

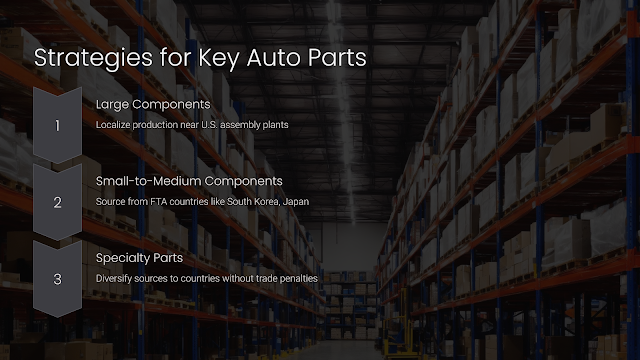

4. Targeted Strategies for Key Auto Parts

The supply chain must adapt differently for major auto parts categories:

A. Large Components (Body Panels, Seats, Dashboards)

- Strategy: Localize production near assembly plants in the U.S. to avoid tariff exposure. Evaluate investments in U.S.-based manufacturing or joint ventures with local suppliers.

- Pro Tip: Use existing partnerships to optimize proximity and reduce logistics costs.

B. Small-to-Medium Components (Electronics, Fasteners, Wiring)

- Strategy: Source from FTA countries like South Korea, Japan, or within Europe to minimize tariff impacts. Strengthen relationships with suppliers in regions with favorable trade agreements.

- Pro Tip: Leverage free trade zones in the U.S. for intermediate processing and assembly to minimize costs.

C. Specialty Parts (EV Batteries, Autonomous Sensors)

- Strategy: Diversify sources by investing in countries that can produce at scale without trade penalties, such as India or Vietnam.

- Pro Tip: Build redundancies into the supply chain to safeguard against policy volatility.

5. Expert Insights: Navigating the Uncertainty

A Complex Balancing Act

Industry experts note that while tariffs may incentivize domestic production, the short-term disruptions and cost escalations could outweigh the benefits. Companies must focus on scenario planning and building resilience into their supply chains.

Real-World Examples:

- 2018 Steel Tariffs: When tariffs on imported steel were introduced, U.S. automakers faced a 25% cost increase for raw materials. The resulting price hikes pushed many manufacturers to renegotiate long-term contracts with suppliers.

- North America as a Strategic Region: With trade uncertainties, automakers must reassess their reliance on Mexico and Canada, balancing the need for cost efficiency with regulatory compliance.

Pro Tip:

Keep a close watch on political developments and lobby for gradual policy implementation to reduce immediate disruption.

Conclusion: Finding Opportunity Amidst Turmoil

The proposed tariffs present challenges but also opportunities for innovation and strategic planning in the automotive industry. Procurement and supply chain professionals should take this as an opportunity to:

- Rethink and diversify sourcing strategies.

- Strengthen relationships with domestic and international partners.

- Advocate for policies that promote stability and growth in the sector.

By proactively addressing these changes, the automotive industry can not only weather the storm but emerge stronger and more resilient in a rapidly changing global market.

- Get link

- X

- Other Apps